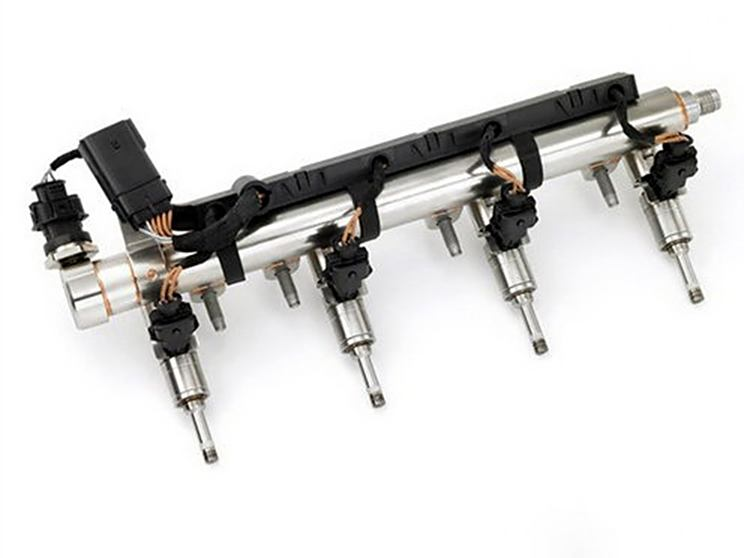

I. Overview of the High-Pressure Common Rail System

The high-pressure common rail system in modern diesel engines represents a major breakthrough in fuel injection technology. Through the coordinated operation of a high-pressure fuel pump, common rail pipe, injectors, and electronic control unit (ECU), this system achieves precise control of fuel injection pressure and timing. As the “heart” of the system, the high-pressure common rail injection pump is responsible for generating and maintaining the required fuel pressure (typically 1800-2500 bar). Its performance directly impacts engine power, fuel economy, and emissions.

II. Common Failure Modes of High-Pressure Common Rail Injection Pumps

1. Insufficient Pressure Buildup: This manifests as reduced engine power and difficulty starting, often caused by piston wear, a faulty fuel metering valve, or a malfunctioning pressure regulating valve.

2. Abnormal Pressure Fluctuation: This leads to unstable engine operation, often caused by camshaft bearing wear or plunger spring fatigue.

3. Fuel Leakage: External leaks are easy to detect, while internal leaks require flow testing. Deterioration of seals is the primary cause. 4. Abnormal noise: This is usually caused by abnormal wear of the camshaft, tappet, or bearings.

5. Electronic control failure: This can be caused by circuit problems such as a shorted/opened metering unit coil or abnormal sensor signals.

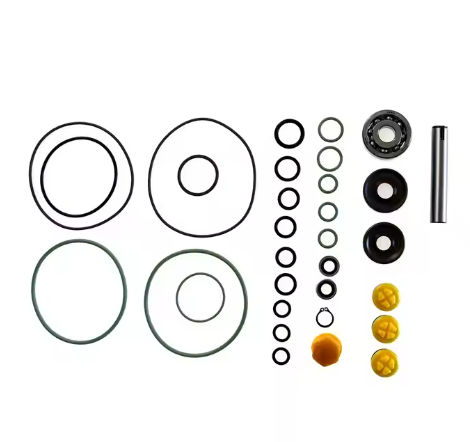

III. Detailed Explanation of Core Components in the High-Pressure Common Rail Injection Pump Repair Kit

1. Plunger Assembly

– Precision plunger pair: Hardness exceeding HRC60, clearance of only 1-3μm, and super-finished surface finish

– Repair Tips: Replace in pairs, lubricate with fuel before installation, and do not disassemble at will

2. Inlet Metering Valve (IMV)

– Two types: electromagnetic or piezoelectric, typically with a resistance of 2-5Ω

– Testing Method: Test valve spool movement via ECU diagnostics or direct power supply

3. Pressure Regulating Valve (PRV)

– Two types: mechanical and electronic

– Key Parameters: Opening pressure must be adjusted to manufacturer specifications, with an error of no more than ±5 bar

4. Seal Assembly

– High-Pressure Seal: Made of PTFE composite material, with a pressure resistance exceeding 2000 bar

– Installation Precautions: Use specialized tools to avoid distortion or scratching

5. Drive Components

– Camshaft: Case carburized and hardened, with a hardness layer depth of 0.8-1.2mm

– Tappet: Ceramic roller design. Cam profile inspection required after wear.

IV. Professional Repair Process

1. Preliminary Diagnosis

– Use a diagnostic tool such as IDS/ODIS to read the actual fuel pressure.

– Perform a high-pressure pump flow test (oil return volume test).

– Check the low-pressure oil line pressure (minimum 6 bar).

2. Standard Disassembly

– Use a torque wrench to remove the pump head bolts in diagonal order.

– Mark the camshaft timing position.

– Categorize and store small parts.

3. Precision Inspection

– Test the plunger assembly for tightness (pressure holding method).

– Measure the cam lift (use a dial indicator; replace if wear > 0.1mm).

– Check the bearing radial clearance (minimum 0.05mm).

4. Key Assembly Points

– Apply special assembly oil to all friction pairs.

– Tighten in stages according to the manufacturer’s specified torque (e.g., Bosch CP3 pump head bolts require 30 Nm + 90°).

– Perform a static seal test (pressurize with test oil to 1.5 times the operating pressure).

5. On-board commissioning

– First, bleed the low-pressure oil line.

– Use a diagnostic tool to activate the metering valve learning function.

– Monitor the fuel pressure curve.

V. Key Quality Control Points

1. Parts Selection: Prioritize OEM-certified brands (such as Bosch, Delphi, and Denso original repair kits).

2. Cleanliness Control: The working environment must meet ISO 4406 16/13/10 standards.

3. Torque Management: Use a calibrated torque tool for critical bolts.

4. Performance Verification: Perform a 100km road test and collect data after repair.

VI. Maintenance Technology Development Trends

1. Application of Intelligent Testing Equipment: Such as an ultrasonic plunger wear detector.

2. Promotion of Remanufacturing Technology: Using laser cladding to repair camshafts.

3. Predictive Maintenance: Predict wear trends through oil spectroscopy.

4. New Energy Adaptation: Research and Development of Biodiesel-Compatible Materials

Maintaining high-pressure common rail fuel injection pumps requires both technical expertise and experience. Maintenance personnel must possess not only mechanical knowledge but also the ability to diagnose electronic control systems. Using high-quality repair kits and standardized procedures ensures that performance after repair is restored to factory standards, avoiding secondary failures caused by improper maintenance. With the implementation of the China VI emission standards, higher requirements are being placed on the maintenance precision of high-pressure fuel systems. Maintenance companies should continuously update their technical equipment and provide personnel training to adapt to the needs of the industry.