What is an Engine Rebuild Kit?

Sealing Components Classification?

Dynamic Sealing Components

Static Sealing Components

What are Dynamic Sealing Components?

Dynamic sealing components typically refer to crankshaft oil seals and valve stem seals.

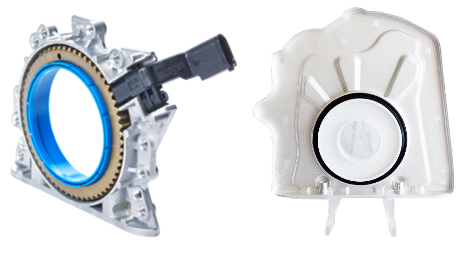

Crankshaft Oil Seal

Fluororubber (FKM) and polytetrafluoroethylene (PTFE) are the preferred materials, as they require strong resistance to high temperatures, oil, and wear. The lip design, combined with the oil return line, ensures that the crankshaft oil seal can isolate oil, dust, and water.

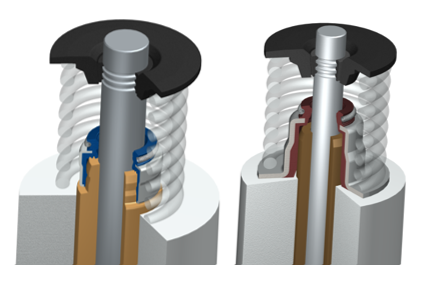

Intake and Exhaust Valve Stem Seals:

Fluororubber (FKM) + External Metal Skeleton The main function of valve stem seals is to prevent engine oil from entering the intake and exhaust pipes, which would cause oil loss and prevent engine oil from entering the combustion chamber, leading to insufficient power. Different lip angles are designed to meet the requirements of different interference fits.

What are Static Sealing Components?

Static sealing components usually include cylinder head gaskets, valve cover gaskets, intake manifold gaskets, exhaust manifold gaskets, oil cooler seals, vacuum pump gaskets, water pump gaskets, turbocharger gaskets, oil pan gaskets, and various sizes of O-rings. These components are made of materials such as metal, metal + rubber, and pure rubber.

The cylinder head gasket withstands the pressure caused by tightening the cylinder head bolts and is subjected to the high temperature and pressure of the combustion gases inside the cylinder, as well as the corrosion of engine oil and coolant. The cylinder head gasket should have sufficient strength and be resistant to pressure, heat, and corrosion. Additionally, it needs to have a certain degree of elasticity to compensate for the roughness and unevenness of the engine block top surface and the cylinder head bottom surface, as well as the deformation of the cylinder head due to gas forces during engine operation.

Valve Cover Gasket

Acrylate rubber (ACM) (-25 to +150°C), mainly functions to prevent oil leakage. Acrylate rubber has the second-best comprehensive performance in terms of heat and oil resistance, next to fluororubber. It is characterized by its resistance to aging, oil, and wear. Its mechanical and processing properties are superior to fluororubber and silicone rubber, and its heat resistance, aging resistance, and oil resistance are better than nitrile rubber, making it the most suitable for the working environment of the valve cover.

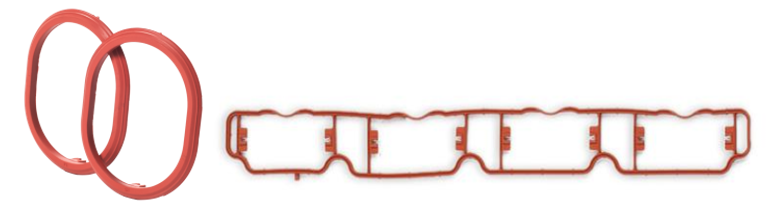

Intake Manifold Gasket:

Fluororubber (FKM) (-20 to +250°C), mainly functions to prevent air leakage. Fluororubber is the most balanced variety among all types of rubber in terms of performance. It has the characteristics of being resistant to high temperatures, aging, water, acids, and wear. The intake manifold is directly connected to the engine cylinder head, and the engine often operates with temperatures fluctuating between 30°C and 130°C, with the cylinder head temperature reaching 130-150°C.

Why Choose Cale?

The engine rebuild kit contains dozens of parts, and the sealing media are also quite complex. Different application environments require suitable materials and product designs to match.

As a highly recommended sealing solution in the independent aftermarket, Cale’s engine rebuild kit has unique product advantages, providing excellent protection and performance enhancement for engines.

Cale’s engine rebuild kits have the advantage of original equipment manufacturer (OEM) fitment. They are co-developed and verified with major automotive manufacturers to ensure perfect matching with various car brands and models, thus ensuring the stability and reliability of sealing performance.

Cale’s engine rebuild kits strictly follow the technical specifications of NOK-FREUDENBERG, striving for excellence from material selection to manufacturing processes. These materials are carefully selected and tested, possessing excellent heat resistance, pressure resistance, and corrosion resistance. The sealing components meet strict quality assurance and can be used in various harsh working conditions.

Whether it is cylinder head sealing, crankshaft sealing, or cylinder head gasket sealing, Cale can provide reliable sealing solutions for both small cars and heavy commercial vehicles, ensuring that the precise dimensions and shape design of the sealing components meet the tight fit of engine parts, preventing the leakage of lubricating oil, coolant, and combustion gases.

How can we help you?

Contact us at the Consulting WP office nearest to you or submit a business inquiry online.